Introduction

According to the liquidus temperature of different critical points, solder solder has high temperature and low temperature solder.The liquidus temperature is higher than that of tin lead eutectic melting point - 183 degrees of solder bar for high temperature solder, high temperature solder is formed when adding a silver, antimony and lead a higher proportion in the solder alloy solder, high-temperature solder is mainly used to main board assembly does not produce change of component assembly; liquidus temperature lower than the tin lead eutectic melting point - 183 degrees of solder bar for low temperature solder and low temperature solder bar is in solder alloy adding bismuth, indium, cadmium solder, mainly used for microelectronic sensors such as low heat resistance of parts assembly.

According to the chemical nature, the common solder bar type has the oxidation resistance solder strip and the high purity low slag solder bar.

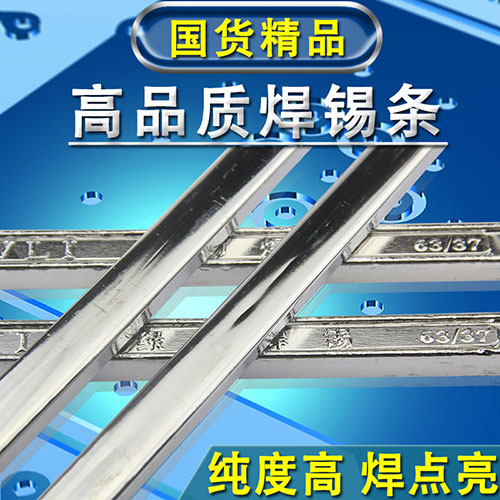

Solder anti-oxidation: have good antioxidant capacity, high mobility, strong welding of, melt dross is few, in immersion and wave soldering little oxidized is economy of province tin solder. Excellent wetting and welding, the solder joint is full and uniform, and the welding effect is excellent.

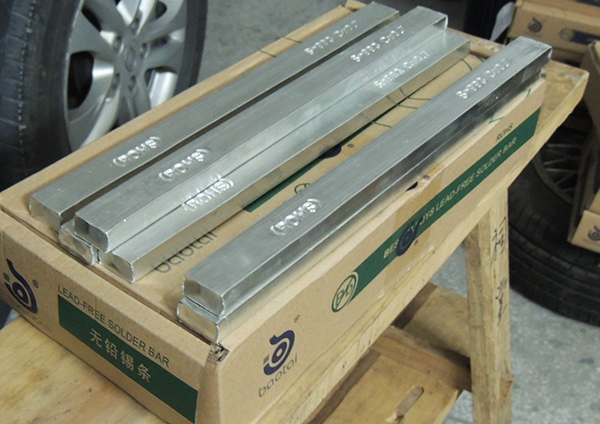

High purity low slag solder bar: the use of the raw material is 100% electrolytic tin, lead or tin lead alloy. By casting or extrusion mold. Therefore, it is suitable for all kinds of welding process because of its high stability, super low slag and high moisture.

More Products